What Juicer Do Juice Shops Use?

Professional juice shops typically use heavy-duty centrifugal juicers like Breville or Omega for high-volume production of hard fruits and vegetables. You'll also find masticating juicers for leafy greens and dedicated citrus juicers for efficient orange and lemon processing. Your choice depends on your menu and volume needs - high-traffic shops often combine multiple types of juicers. Understanding the pros and cons of each type will help you make the best equipment investment for your operation.

Understanding Different Types of Commercial Juicers

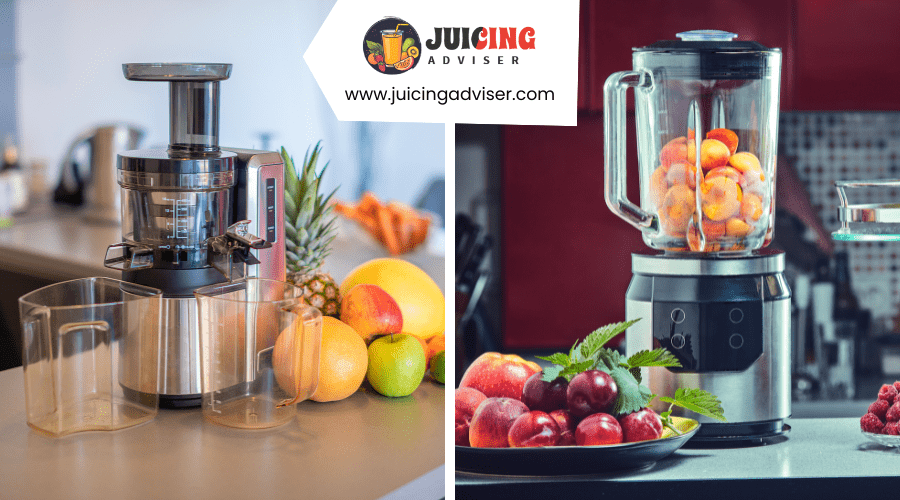

Commercial juice shops rely on several specialized juicer types to meet their varied production requirements. You'll find centrifugal juicers handling the bulk of hard produce like apples and celery, as they're designed for rapid, high-volume operations.

Masticating juicers take on the tougher ingredients, efficiently extracting juice from leafy greens while keeping foam production minimal.

For businesses focusing on citrus drinks, dedicated citrus juicers offer high-speed processing of lemons, limes, and oranges. When it comes to specialty items, wheatgrass juicers tackle grasses and herbs, while sieve juicers process semi-solid foods and purées. Each type serves a specific purpose in commercial settings, from juice bars to restaurants, allowing businesses to create diverse beverage menus while maintaining efficiency and quality.

Centrifugal force extraction enables these machines to process large quantities of produce at speeds between 3,000 and 16,000 RPMs.

Popular Juicer Brands in Professional Juice Shops

While establishing a professional juice business requires careful equipment selection, several trusted brands consistently emerge as industry leaders. You'll find high-powered centrifugal juicers from Breville, Omega, and Kuvings dominating juice shop counters, offering rapid juice production for high-volume orders.

For leafy greens and maximum yield, commercial masticating juicers from Hurom and Omega are go-to choices among juice professionals. If you're focusing on citrus drinks, Zummo and Santos provide specialized commercial citrus juicers that deliver efficient extraction. Shops offering wheatgrass shots typically rely on dedicated juicers from Samson and Tribest.

Many successful juice businesses also invest in versatile commercial juicers from Hamilton Beach and Nutrifaster, which can handle various produce types while maintaining consistent output throughout busy service hours. The slow grinding process of commercial masticating juicers helps preserve essential nutrients and enzymes, making them ideal for juice shops focused on delivering premium quality beverages.

Key Features of Professional-Grade Juice Equipment

Professional-grade juice equipment stands apart from consumer models through several essential features that enable efficient, high-volume production. You'll find wide feeding chutes that reduce prep time and powerful motors built to run continuously throughout the day.

When you're looking at specific types, centrifugal juicers offer rapid extraction speeds and versatility for various produce. Masticating juicers, while operating more slowly, deliver higher yields and better nutrient retention. If you're focused on citrus, automated reamers provide quick, consistent results for lemons, limes, and oranges.

Commercial-grade cold press juicers represent the premium segment, featuring heavy-duty construction and advanced extraction technology. These machines maximize juice quality while minimizing oxidation. All professional equipment includes safety features, easy-clean components, and durable materials designed to withstand constant use in busy juice shops. Most commercial juicers utilize high-wattage motors between 800 and 1000 watts to handle tough, fibrous produce without overheating during extended use.

Production Volume and Business Scale Considerations

The scale of your juice business directly impacts which commercial juicer will serve you best. If you're running a high-volume operation serving dozens of customers per hour, you'll want to invest in commercial-grade centrifugal juicers that can quickly process large amounts of produce.

For smaller establishments or those specializing in specific juice types, masticating juicers like the Nama J might be more suitable. These machines excel at extracting juice from leafy greens and provide higher yields, though they work at a slower pace.

If your business model includes both rush hours and specialty drinks, consider equipping your shop with both types of juicers. This dual-equipment approach lets you handle peak times efficiently while still offering premium cold-pressed options to customers who prefer them.

Maintenance and Cleaning Requirements for Commercial Juicers

Maintaining a rigorous cleaning schedule is essential for any juice shop's success and equipment longevity. Regular cleaning and proper disassembly of your commercial juicer's components help prevent bacterial growth and guarantee food safety standards are met.

- Disassemble and rinse all removable parts daily, including the juicing screen and pulp container.

- Allow components to air-dry completely after each cleaning session.

- Perform deep cleaning weekly using mild detergent and warm water to remove residue.

- Inspect and replace worn parts regularly, such as cutting discs and feed chutes.

Health Department Compliance and Safety Standards

Beyond routine cleaning procedures, operating a juice shop requires strict adherence to health department regulations and safety standards. You'll need to obtain proper permits and develop a HACCP plan that outlines your food safety protocols. The health department mandates specific guidelines for produce handling, equipment sanitization, and cross-contamination prevention.

Your staff must be thoroughly trained in proper sanitization methods, personal hygiene practices, and safe juicing procedures. Regular health department inspections will evaluate your compliance with local food safety codes, including proper washing of produce, cleaning of equipment, and maintenance of storage containers. You'll need to maintain detailed documentation of your cleaning schedules, temperature logs, and sanitization procedures. Meeting these requirements isn't just about following rules—it's essential for protecting your customers' health and your business's reputation.

Cost Analysis and Return on Investment

Making smart financial decisions about commercial juicers requires careful consideration of both upfront costs and long-term returns. When you're evaluating different models, focus on machines that efficiently convert produce into small pieces and maximize juice yield while separating juice and pulp effectively.

Your initial investment of $500-$2,000 can deliver impressive returns through:

- High profit margins from fresh juice sales

- Minimal operating costs beyond produce expenses

- Quick recovery of investment within 6-12 months

- Low maintenance and energy requirements

To optimize your ROI, choose a juicer that processes various ingredients efficiently while minimizing waste. Strategic pricing based on your ingredient costs and market demand will help generate profitability. Remember that investing in quality equipment upfront often leads to better long-term financial outcomes through improved efficiency and durability.

Maximizing Efficiency in Commercial Juice Operations

Successfully running a commercial juice operation hinges on streamlined processes and smart equipment choices. To maximize efficiency, you'll want to contemplate commercial juicers that match your specific production needs.

High-volume centrifugal juicers are ideal when you need to process large quantities quickly, thanks to their wide feed chutes and powerful motors. They're perfect for handling most fruits and vegetables with minimal prep time.

If you're focusing on leafy greens or want to reduce waste, masticating juicers offer better yield and less foam, though they operate more slowly. For citrus-heavy menus, dedicated citrus juicers can drastically speed up production.

Keep your operation running smoothly by choosing machines that are easy to clean and maintain. This reduces downtime between batches and guarantees consistent output throughout busy service hours.